Processing Technologies

How can we innovate better as an industry?

Australian manufacturing produces some of the worlds best meat. This will continue. Our commitment to innovation – in product, operations, business systems, communications, export, industry collaboration, environment, etc, is the epicentre of the Australian red meat industry

Jul 28, 2021

This project developed a prototype system that can collect, transfer and place hides onto pallets and into bins and was installed and proven in the JBS hide processing facility in Dinmore.

The pr...

Video

Jul 21, 2021

This video explains the COVID-19 vaccination process

Report

Jul 15, 2021

This project has developed a suitable boning room concept design for small micro size processing plants. This project was completed specifically for Jimbour Beef and Bacon (JBB) and has applications...

Report

Snapshot

Apr 9, 2020

The current practice of removal of cutting out button and flat bones from a striploin beef primal piece requires manual effort and separation using a powered cutter as well as sharp knives. For the ...

Report

Snapshot

Nov 18, 2019

Meat processing plants suffer significant labour costs and OH&S risks associate with the manual bagging of meat cuts after processing. This project aims to examine the most effective way of bagg...

Report

Apr 10, 2019

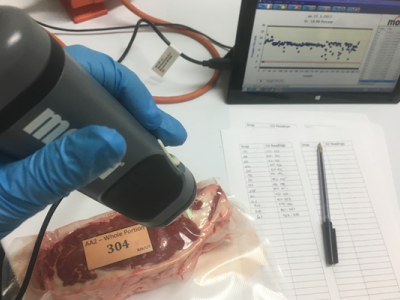

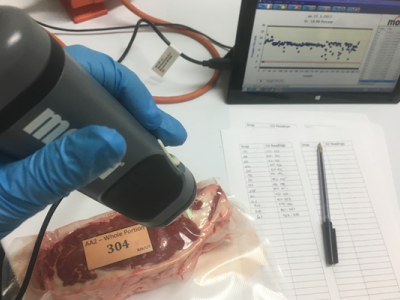

Chemical Lean (CL) is defined as the amount of lean red meat compared to the amount of fat in a meat sample. Its determination by an approved method is a mandatory AUS-MEAT requirement for any expor...

Report

Apr 5, 2019

This project evaluated the TenderSpec TM beef classification system for tenderness and marbling. The objectives were to evaluate this U.S. system against Australian cattle to identify tender c...

Report

Feb 5, 2019

This project was undertaken to develop a roadmap for the use of intelligent automation (IA) by the Australian meat processing industry. It is intended to pave the way for building an enabler in the ...

Report

Dec 20, 2018

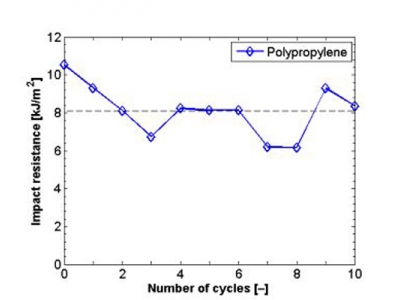

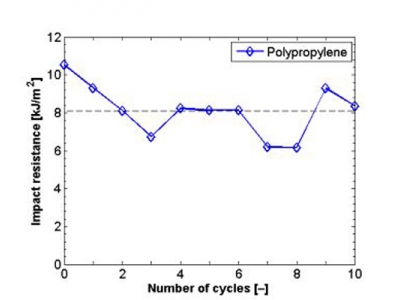

The project assessed the suitability of dry-ice blasting for polymer-based conveyor belts used in the meat processing industry. Investigations were undertaken to determine the effects of thermal var...

Report

Jul 13, 2018

Much advancement has occurred in the field of smart meat packaging, and there is great potential for these to be used as tools that respond to challenges faced by the red meat industry.

This proj...

Report

May 23, 2018

The purpose of this project was to explore the feasibility to extend the usefulness of the X-ray scanning of a carcass to further downstream carcass break-up operations by the use of the carcass&rsq...

Report

May 18, 2018

This project considered opportunities for introducing Industrial Internet of Things (IIoT) solutions to the Australian red meat processing industry, aiming to improve productivity for the worker and...

Report

Feb 12, 2018

Liquefied CO 2 is used on a daily basis in the red meat industry to produce dry ice snow for product cooling applications. Traditionally, it has been cost prohibitive for abattoirs to invest in the...

Report

Jan 22, 2018

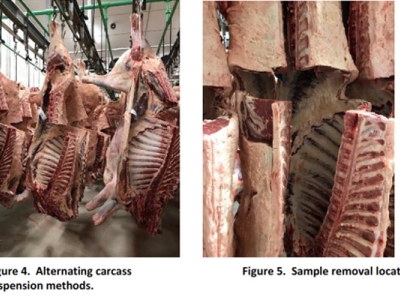

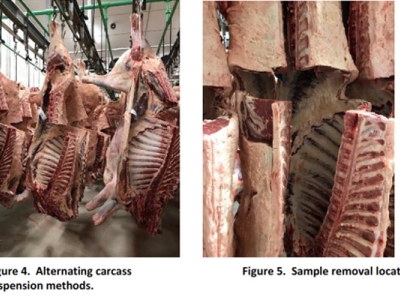

The purpose of this project was to investigate the ability of an automated beef rib cutting system to accurately perform objective carcase measurement (OCM) on beef sides for fat, lean and bone comp...

Report

Jan 11, 2018

This project has researched the processes of fat trimming with the objective to determine automation feasibility to achieve trimming leaving a uniform layer of fat on beef striploin primal pieces.

...

Report

Dec 13, 2017

The objective of this project was to develop, install and test an automated container loading system for the packing of meat cartons into a refrigerated shipping container. This will be a pilot syst...

Report

Dec 13, 2017

Manual frenching of lamb racks requires skilled knife-work and consumes considerable labour resources. Current commercial frenching solutions (that require reduced labour) result in significant wate...

Report

Dec 12, 2017

The aim of this project was to present an overview of the utilisation of proteins from side stream raw materials with a focus on hydrolysed proteins.

The goal was to gather knowledge related to q...