Processing Technologies

How can we innovate better as an industry?

Australian manufacturing produces some of the worlds best meat. This will continue. Our commitment to innovation – in product, operations, business systems, communications, export, industry collaboration, environment, etc, is the epicentre of the Australian red meat industry

Report

Dec 12, 2017

Robotic automation and hybrid processes for bandsawing have a wide array of advantages for the red meat industry, including lower production costs, reduced worker fatigue, increased workplace safety...

Report

Dec 12, 2017

The project investigated the detail design challenges and conditions to integrate a CO2 capture plant into an existing abattoir process system.

The project also outlined high risk components and ...

Report

Dec 12, 2017

Beef carcase splitting is currently undertaken by trained and experienced saw men, often using splitting saw operated on hydraulic platforms.

Due to recent progress in automating other aspects of...

Report

Dec 12, 2017

The objective of this project was to evaluate the benefits and possibilities of adapting the existing automatic pork bung handling equipment, which is in use in Denmark, to slaughter lines for lamb ...

Report

Dec 11, 2017

In Australia, primal cut meat is generally compacted into frozen blocks and cut into “cubes” for bulk packaging or in bags of fixed weight for export. Tests conducted indicate that cutti...

Report

Dec 11, 2017

The main objective of this research project was to investigate the potential for self-cleaning or low fouling membranes in the Red Meat industry for tallow recovery.

The philosophy behind the pro...

Report

Dec 11, 2017

Red meat processors can generate large volumes of wastewater rich in both organic contaminants and nutrients and can therefore be strong candidates for treatment processes aimed at recovery of energ...

Report

Dec 11, 2017

Barriers exist at all stages in the supply chain for the development of new, bovine derived value added products. By speaking with stakeholders at all stages in the supply chain, we developed an und...

Report

Dec 7, 2017

Meat processing plants suffer significant labour costs and workplace health and safety risks associated with the manual picking and packing of primal cuts after processing.

As such, the successfu...

Report

Nov 30, 2017

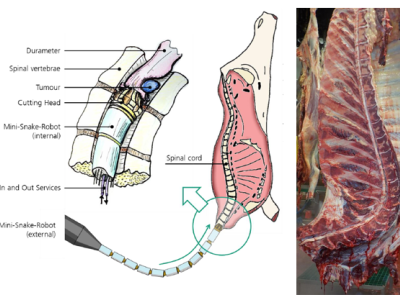

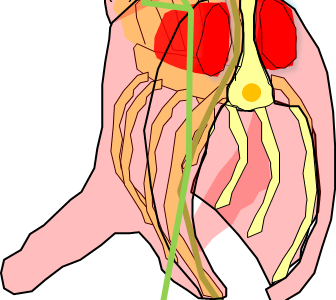

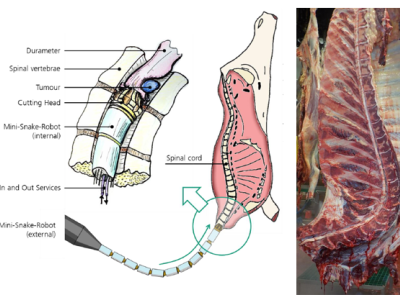

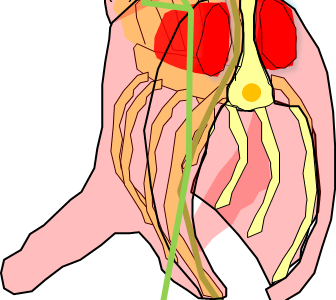

Spinal cord removal and splitting have remained manual processes in slaughter houses around the world, due to the variability of the carcasses and the processes themselves posing significant challen...

Report

Nov 30, 2017

In order to understand industry considerations for transitioning an existing plant into a cellular format, four high volume Australian red meat processors participated in a series of surveys and int...

Fact Sheet

Jun 20, 2017

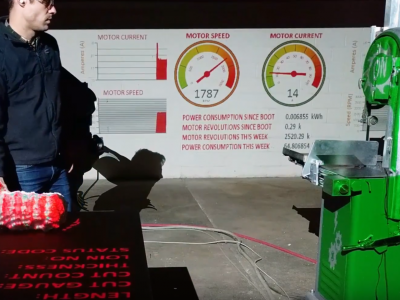

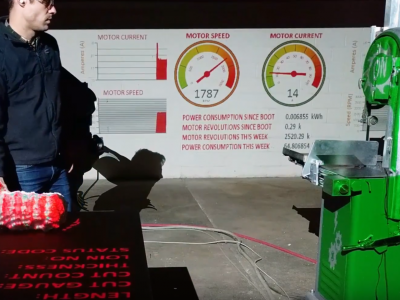

The innovation devised from Primo Scone focuses om the operation of bandsaws in a processing environment. Two key problems face processors with regards to the operation of this machinery.

Anecdot...

Report

Snapshot

Jun 14, 2017

The meat industry has a major requirement to automate its processes of slaughtering and meat preparation including primal cutting, sub-primal breakup and de-boning.

This project was proposed in 2...

Report

May 19, 2017

This project was a pilot study undertaken to verify whether or not meat (lamb) can be safely maintained in a hypobaric (vacuum) environment for 35 days without appreciable loss of weight or spoilage...

Snapshot

Dec 23, 2016

Scott shall utilize its technology and intellectual property from the Leap II hindquarter boning robot along with lessons learnt in the manual-assist Beef Boning Unit to develop a manual assist devi...

Report

Nov 16, 2016

Primal cut picking and packing is currently a labour intensive meat packing process which is completely manual. As a result of the technical complexities involved in this task, there is currently no...

Report

Oct 7, 2016

First Stage To Research & Develop A User Requirement Specification & Present A Prototype Build Cost & Timeline.

A year ago, Applied Robotics was contracted by the AMPC (under AMPC Pro...

Report

Snapshot

Jun 20, 2016

This report documents the results of an investigation to determine if red meat processing facilities would benefit from the use of wearable technologies.

Wearable technologies offer the abil...